ICR has placed itself in a relevant position as an acoustic engineer in the international railway sector during the last decades, thanks to the trust placed on the main European rolling stock manufacturers.

Work Procedure

The working methodology used is based on techniques of forecasting close to home, on measurements of real shifts and vibrations that allow minimizing the theoretical speculation. The ability to tract both the aeri soroll and the structural soroll of each element (subsystem) that forms the train and in time of response, including not only the contribution of forces (Transfer Path Analysis) but also the quantification of the paths of soroll and vibrations (Advanced Transfer Path Analysis). This service meant a considerable reduction of waste in the new train model.

It is necessary to point out that a typical train and quantified characteristics of the fonts used to make the matérix slings, ICR is developing a numerical model that allows both the prediction of the level of slings and vibrations of a new train model as well as the calculation of the solutions to be applied in order to reduce the level of slings to the interior.

Services

Some of the services offered are:

–Advanced transfer path analysis (TPA and ATPA) of noise and vibration.

-Vibro-acoustic contribution of each train element to measured noise at a point in the interior.

-Vibro-acoustic contribution of auxiliary equipment to the train interior noise.

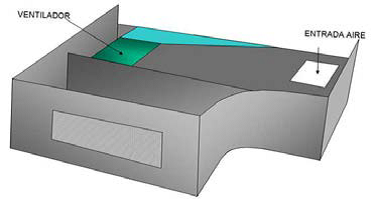

-Influence of airflow separation on internal noise.

-Influence of turbulent boundary layer pressure on internal noise.

-Theoretical and experimental models for predicting rolling noise.

-Theoretical and experimental models for predicting the compression wave generated by an incoming high-speed train in a tunnel.

-Theoretical and experimental models for predicting Squeal noise.

-Theoretical and experimental models for predicting impact noise.

-Theoretical and experimental models for predicting aerodynamic noise in high-speed trains.

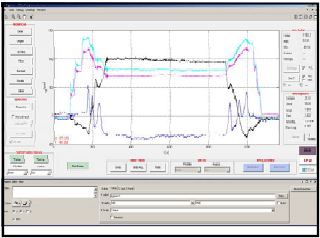

-Software development made to measure by vibroacoustic analysis.

-Fluid dynamic calculations (CFD). Aeroacoustic calculations (CAA).

-Dynamic and vibroacoustic calculations FEM and BEM.

-Forecasting of the acoustic environmental impact due to train passage.

-Custom design of mufflers and acoustic solutions……